FACILITIES

From one end to the other, our 3300 m2 facility is purpose-built to ensure swift handling of large capacity hydraulic cylinder overhauls to minimise downtime while keeping a tight grip on quality at every stage.

Hardchrome Sales is centrally located and is in close proximity to all major transport companies, allowing a fast delivery and return service. With a workforce of over 38 people, we have one of the largest capacities for end-to-end overhaul of Hydraulic Cylinders in Western Australia, including rod, barrel, gland, piston and clevis manufacture, and re-chroming of piston rods, shafts and pins.

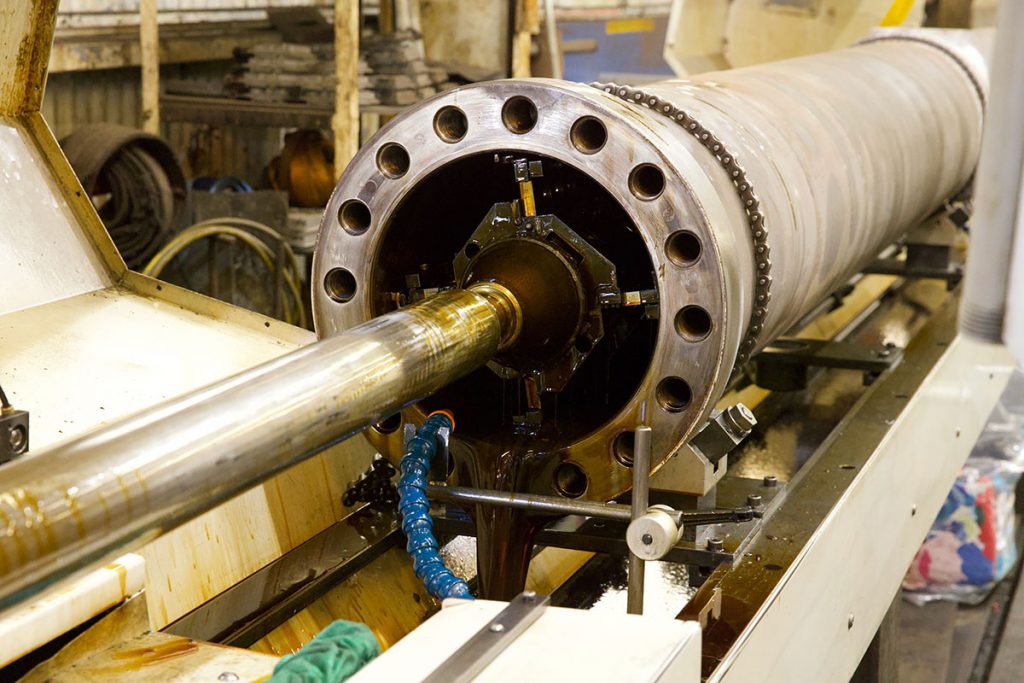

Our completely in-house operation includes a multitude of plating tanks of different dimensions, with some of the largest and deepest in Australia. Our operation has everything needed to swiftly process repairs – including 8 meter centre lathe, 4 meter CNC lathe, large cylindrical grinders, horizontal borers, state of the art honing machine, automatic ID welders, and heavy craneage to handle the largest cylinders.

7 tanks of various dimensions makes Hardchrome Sales the largest-capacity hard chrome plating operation in WA with some of the largest and deepest plating tanks in the country.

Our lathes allow us to process components from 1” to 40” diameter and up to 8m long, including a high speed CNC lathe for manufacture of new piston rods and other components up to 4 meters in length.

Two large horizontal borers with 5 tonne table capacity are equipped for line boring, with digital readouts to maintain accuracy.

With some of the largest cylindrical grinders supporting our production needs, our chroming department can grind piston rods up to 5 meters in length whilst also having the capacity to grind small pump shafts.

Our welding department is equipped to perform the latest welding processes, with fast accurate automatic welding machines delivering incredible clean, high quality results:

- Automated Internal Diameter Welding

- Automatic Submerged Arc Welding

- Mig Welding

- Tig Welding

- Stick Welding

All welds are tested using appropriate engineering methods to ensure integrity and provide complete confidence in every repaired component.

Hardchrome Sales operate one of the largest honing machines which incorporates the latest in CNC technology, capable of honing up to 6 meters open ended tubes, with automatic surface variance correction technology, can obtain the fine surface finishes that are required in today’s industries. With two variable speed honing machines operating we can turn items around very quickly from the smallest diameters to the largest diameters of today’s mining and earthmoving equipment.

Our fitting shop is equipped with four heavy-duty disassembly benches, nut crackers and torque multipliers capable of dismantling the largest hydraulic cylinders, including mining excavator cylinders, luffing cylinders and blast hole drill pull-down cylinders. Our fitting shop is equipped to perform in house non-destructive testing and precision measurements, and our hydraulic test bench is configured to perform a range of test procedures up to 5000 psi.